About one fifth of electricity in the United States comes from natural gas power plants. Water is required first to extract natural gas from its underground source and then to transform the fuel’s chemical energy into electricity.

Electricity generation

More than 80 percent of natural gas-fired generation in the United States comes from natural gas combined-cycle (NGCC) power plants. The rest are simple gas combustion turbines (9 percent) or simple steam turbines (9 percent).[1] An NGCC plant first uses a gas combustion turbine to generate electricity, then uses the waste heat to make steam to generate additional electricity in a steam turbine. Because gas combustion turbines require no cooling (having no steam to condense), the overall combined cycle system requires much less water for cooling than traditional steam turbine technologies.

Because the amount of cooling necessary is much less per unit of electricity output in NGCC plants than in coal or nuclear plants, dry cooling systems are more economical for NGCC plants than for other thermoelectric options. A dry cooling unit in a NGCC plant can only be one third the size of a dry cooling unit for a coal or nuclear plant with the same electricity output.[2] About 8 percent of natural gas combined cycle plants in the United States use dry cooling technology; 80 percent rely on recirculating systems. Fewer than seven percent use once-through cooling.[3]

| Once-through | Recirculating | Dry-cooling | ||||

| Withdrawal | Consumption | Withdrawal | Consumption | Withdrawal | Consumption | |

| Natural gas (steam turbine) | 10,000 - 60,000 | 95 - 291 | 950 - 1,460 | 662 - 1,170 | 0 - 4 | 0 - 4 |

| Natural gas (combined cycle) | 7,500 - 20,000 | 20 - 100 | 150 - 283 | 130 - 300 | 0 - 4 | 0 - 4 |

| Natural gas (combustion turbine) | 0 | 0 | 0 | 0 | 0 | 0 |

| Water withdrawn and consumed for power plant cooling, in gallons of water required per megawatt-hour of electricity produced[5]. | ||||||

Fuel extraction

Natural gas in the United States has traditionally been extracted from deep vertical wells that require relatively small amounts of water for drilling but that produce more than 200 billion gallons of water per year that surfaces with the gas on extraction.[5] This "produced water" is often trapped in these underground formations alongside natural gas.[6] The main methods of disposing of produced water involve pumping it back into oil- or gas-producing wells to bolster production, or injecting it deep into other formations below usable groundwater resources.[7]

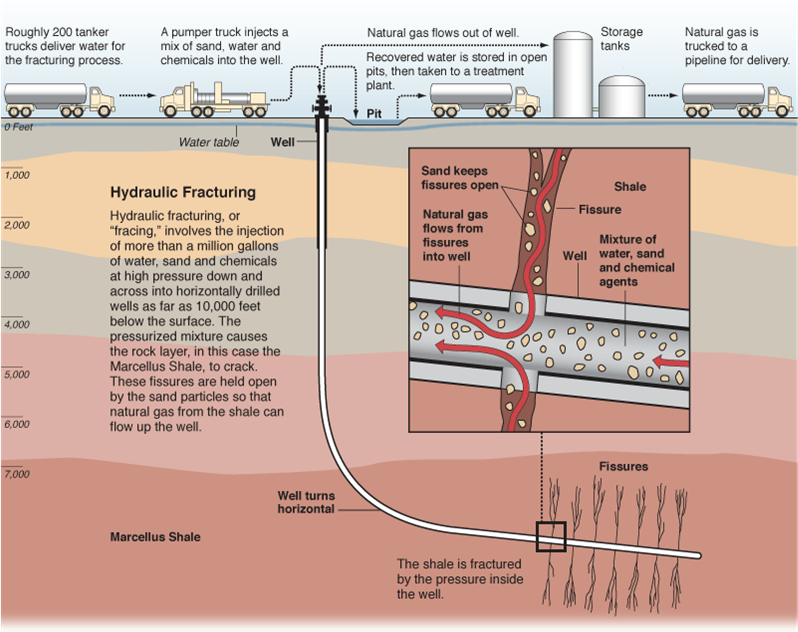

In recent years, natural gas from shale gas deposits has become a major new source in the United States. These new supplies are less readily accessible than conventional deposits, and extracting the gas requires a process called hydraulic fracturing or “hydrofracking.” The process involves drilling vertically down to where the gas is trapped and then turning to follow the deposit horizontally. A mixture of water and chemicals sent through the drill hole at high pressures creates fractures in the rock and allows the trapped natural gas to escape to the surface. According to the EIA, shale gas made up about one-third of total U.S. natural gas production in 2012, and will grow to nearly half by 2040.[8]

Hydrofracking has become controversial because of concerns about groundwater being contaminated with natural gas and the chemicals used in the process. A single hydrofracking treatment can yield 15,000 gallons of chemical waste from the fracking fluids.[9] Due to the failure of the industry to disclose the mix of chemicals used in the process and to its successful lobbying to exempt the process from the Federal Clean Water and Safe Drinking Water Acts, concerns have emerged about the ability of local wastewater facilities to properly treat the produced water.[10],[11] Recognizing the potential health and environmental impacts on local water sources, the EPA is studying water impacts of hydrofracking on gas shale production.[12]

In addition to concerns about water quality, water quantity is also an issue. A single hydrofracked well can require several million gallons per treatment — dozens of times what is used in conventional vertical drilling.[13],[14],[15] Withdrawing this amount of water over a short period of time can strain local water sources.

Fuel processing

After the gas is extracted, an additional 400 million gallons of water per day are consumed for natural gas refining and pipeline operations.[16]

For more data on lifecycle water use, see Meldrum et al. 2013.

Sources

[1] Energy Information Administration (EIA). 2012. Annual electric utility data. Washington, DC.

[2] Government Accountability Office (GAO). 2009. Energy-Water Nexus: Improvements to Federal Water Use Data Would Increase Understanding of Trends in Power Plant Water Use. Washington, DC.

[3] Union of Concerned Scientists. 2012. UCS EW3 Energy-Water Database V.1.3. www.ucsusa.org/ew3database.

[4] J. Macknick, R. Newmark, G. Heath, and K.C. Hallet. 2012. Operational water consumption and withdrawal factors for electricity generating technologies: a review of existing literature. Environmental Research Letters. 7 doi:10.1088/1748-9326/7/4/045802.

[5] US Department of Energy (DOE). 2006. Energy Demands on Water Resources: Report to Congress on the Interdependency of Energy and Water.Washington, DC.

[6] US Department of Energy (DOE). 2009. Oil and Natural Gas Water Resources Program. Washington, DC.

[7] DOE. 2006.

[8] Energy Information Administration (EIA) 2013. AEO2013 early release overview. Table 1: Comparison of projections in the AEO2013 and AEO2012 reference cases, 2010-2040. Washington, DC.

[9] US Geological Survey (USGS). 2009. Estimated Use of Water in the United States in 2005. Reston, VA.

[10] New York State Water Resources Institute. 2010. The Marcellus Shale and natural gas.

[11] A.J.Daniel, and M. Layne. 2008. Hydraulic Fracturing Considerations for Natural Gas Wells of the Marcellus Shale. ALL Consulting.

[12] Environmental Protection Agency (EPA). 2010. Natural gas Extraction - Hydraulic Fracturing.

[13] P. Applebome. 2010. Will New York Rebel Against Fracking? Green Blog - NYTimes.com.

[14] Chesapeake Energy. 2013. Hydraulic Fracturing Facts. Oklahoma City, OK.

[15] US Geological Survey (USGS). 2009. Water Resources and Natural Gas Production from the Marcellus Shale. Reston, VA.

[16] DOE. 2006.